Breaking the Mold: How Logitech is Tackling Single-Use Plastic, One Package at a Time

Unboxing a new product is more than just opening a...

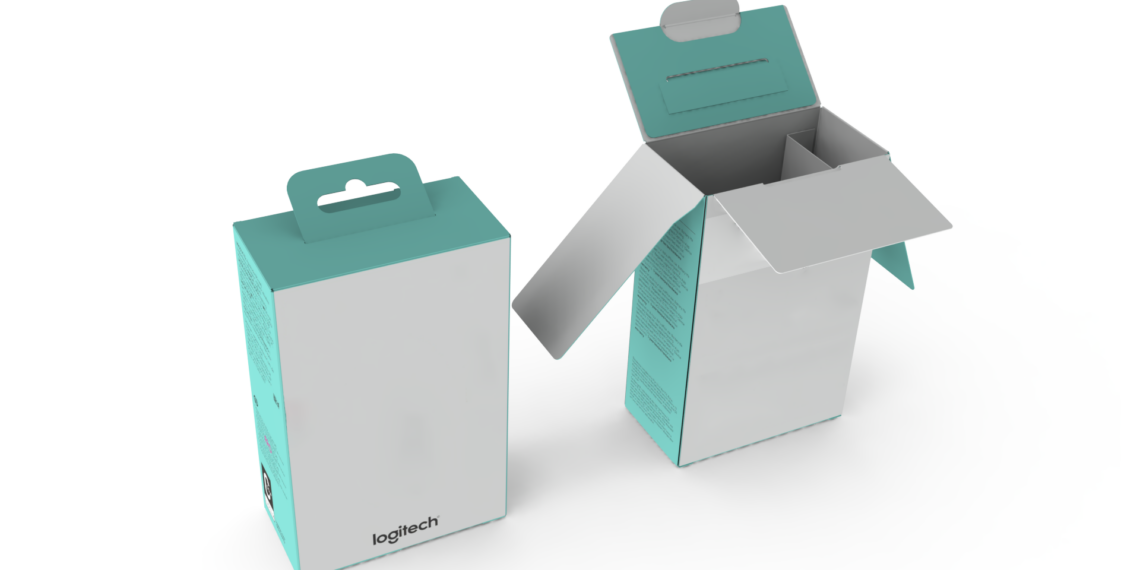

The Face Behind Logitech’s Sustainable Packaging Revolution

Contrary to popular belief, packaging isn’t all just paper and...

Logitech Wins Four iF Design Awards, Recognizing Design Excellence Across Categories

With strict criteria and a growing emphasis on sustainability, the...

Celebrating Role Models Who Are Shaping the Future of STEM

This International Women’s Day, we’re celebrating women breaking barriers in...

WORK & PLAY

Related Posts

Join Our Newsletter

Copyright © 2024 by Logitech.